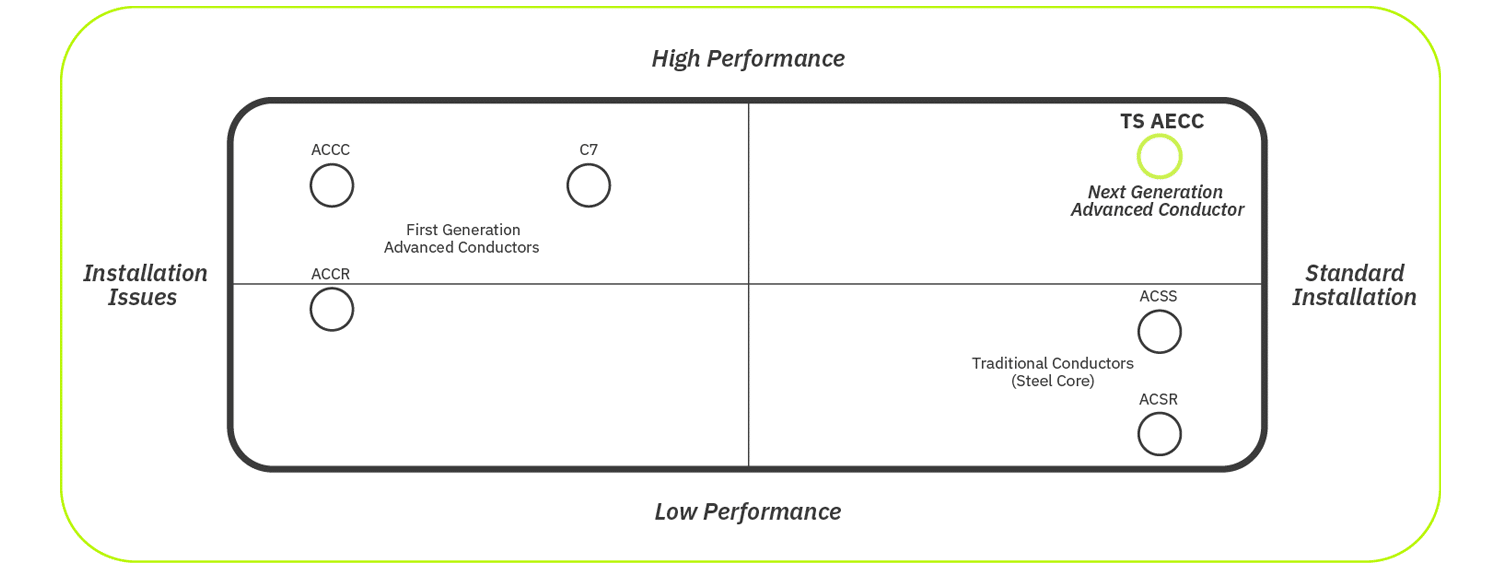

Next generation advanced

conductors.

Problem.

Considered delicate, difficult to work with, and easy to break.

Requiring specialized equipment and training. Less-than-perfect handling may jeopardize performance and safety.

Longevity concerns due to the core’s vulnerability to environmental conditions.

Solution.

Fully compatible with standard installation and maintenance practices.

No specialized equipment or training required.

Encapsulated core is fully protected from environmental conditions.

Award-winning innovation.

Aluminum Encapsulation

Pre-Tensioned Carbon Core

Mainstream solution for grid modernization.

AECC doesn’t work around limitations—it removes them entirely. The result is a mainstream solution for grid modernization that meets rigorous utility safety and reliability standards.

TS Conductor's award-winning design optimizes three critical components: a carbon fiber core (without glass fibers) that delivers maximum strength and stiffness, a seamless aluminum encapsulation layer that preserves core pre-tensioning and provides multiple protective functions, and trapezoidal strands made from annealed aluminum that maximize conductivity. This integration achieves superior performance across all key metrics while maintaining the built-in safety and reliability of traditional options, earning recognition from organizations like the U.S. Department of Energy, Public Utilities Fortnightly, S&P Global Platts, and Bloomberg NEF.

Standard installation

and maintenance.

AECC is the only advanced conductor that is fully compatible with traditional ACSR/ACSS installation and maintenance practices. Rather than expecting perfection from line crews, TS Conductor has designed a product that’s inherently robust and forgiving.

-

Standard Compression Fittings

AECC’s aluminum encapsulation layer acts as a cushion, protecting the carbon composite core during crimping and ensuring full compatibility with standard fitting approaches. Compression fittings achieve 100% compaction around the core, blocking moisture and oxygen. The airtight seal and thick aluminum encapsulation protect the core from environmental degradation, ensuring long-term performance.

-

Standard Bending Radius

During manufacturing, the carbon core is pre-tensioned and tightly encapsulated in aluminum to preserve the tension. This built-in tension, combined with the encapsulation’s structural support, allows the conductor to resist compression stress when bent - preventing core buckling or breakage. As a result, AECC maintains the same bending radius requirements as ACSR/ACSS, consistent with IEEE 524 standards.

-

Standard Storage

Unlike some advanced conductors, AECC requires no special storage conditions because the core is completely sealed and protected from moisture ingress and resulting matrix plasticization. It can be stored just like traditional conductors, simplifying logistics.

Longevity and resilience.

AECC is built to withstand harsh environmental conditions and extreme weather events, ensuring long-term integrity and performance.

Environmental conditions.

-

Galvanic Corrosion

Airtight aluminum encapsulation blocks moisture and oxygen, preventing conditions that lead to galvanic corrosion.

-

Oxidation and Moisture

Sealed design prevents oxygen and water ingress, safeguarding against oxidation and moisture-induced degradation.

-

UV Radiation and Ozone

Even if the outer cable strands separate ("birdcaging"), the composite core remains protected from UV damage and ozone.

-

Aeolian Vibration

Annealed aluminum strands and trapezoidal wire design provide natural damping through creep and inter-strand friction, protecting against fatigue damage.

-

Galloping

Enhanced torsional stiffness, minimal thermal sag, and reduced ice adhesion and aerodynamic lift all work to control galloping behavior.

Extreme weather

events.

AECC's resilience in extreme conditions ensures long-term grid reliability, a critical factor for utilities investing in infrastructure built to last decades:

-

Ice

The greater strength and stiffness of the all-carbon core outperforms glass fiber alternatives, handling heavy ice loads with minimal sag. High-temperature operation enables rapid de-icing while maintaining safe clearances.

-

Wind & hurricanes

Streamlined design with trapezoidal strands reduces wind resistance, while the AECC’s lighter weight and lower tension minimize the structural stress that can otherwise occur during high-wind weather systems.

-

Fire

Annealed aluminum's heat resistance and low thermal sag at high temperatures improve survival odds during wildfires, reducing the potential for outages and the risk of ignition sources.