There’s a reason TS Conductor’s Aluminum Encapsulated Carbon Core (AECC) technology has been recognized with prestigious awards from the U.S. Department of Energy, Public Utilities Fortnightly, S&P Global Platts, and Bloomberg NEF. AECC technology delivers the increased capacity and minimal sag of advanced conductors while maintaining the safety, reliability, and ease of installation expected from traditional conductors. This breakthrough performance comes from the modern materials science and practical engineering of three critical components: the pre-tensioned carbon fiber composite core, the aluminum encapsulation protective layer, and the fully-annealed aluminum conducting strands. AECC’s patented design optimizes each element while ensuring they work together as an integrated system.

Pre-Tensioned Carbon Core

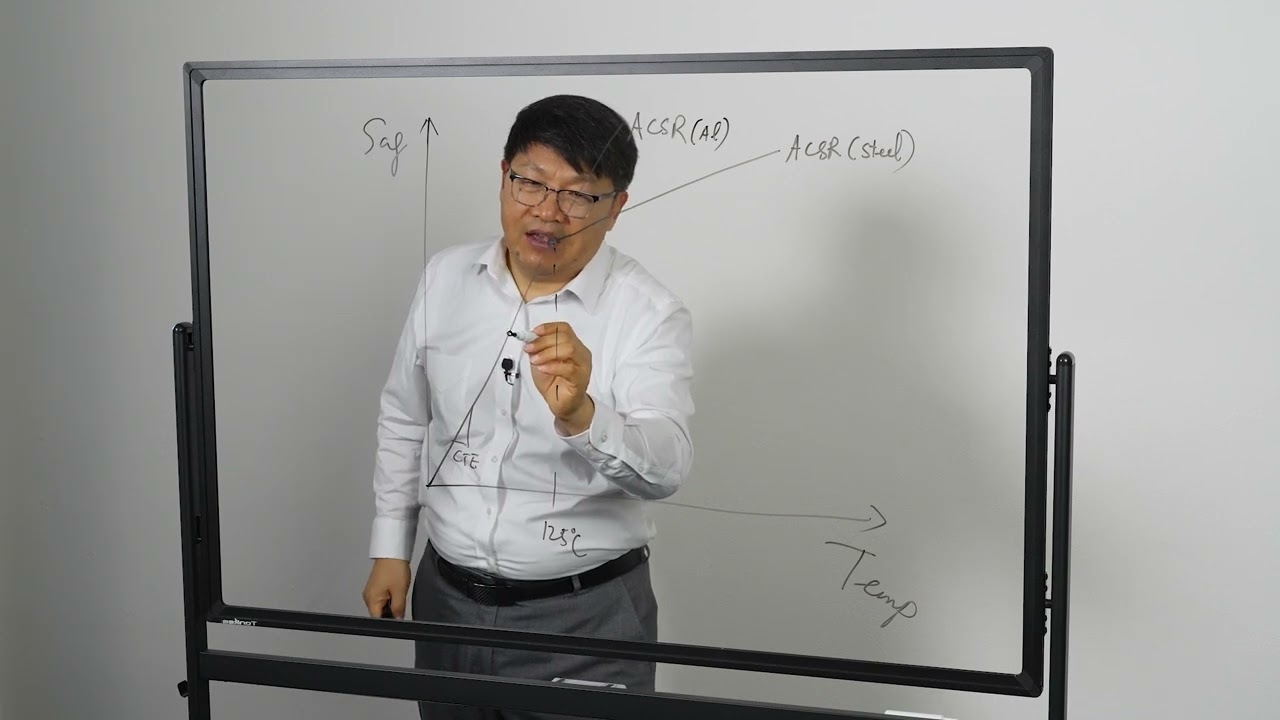

Modern materials science offers no better solution for overhead conductors than carbon fiber composite. Its exceptional strength-to-weight ratio and near-zero thermal expansion are ideal for this demanding application. The carbon fiber core is both stronger and lighter than steel, allowing us to add significantly more aluminum conducting material while maintaining the same overall weight and tension as traditional conductors. The low thermal expansion allows utilities to increase line capacity by operating at higher temperatures while maintaining required clearances.

While carbon fiber composites offer superior tensile strength, they have a well-known materials science challenge: their compressive strength is only 60-70% of their tensile strength. This becomes critical during installation, where bending forces create compression on the under layer of any bend. We address this through pre-tensioning during manufacturing, which we preserve with our aluminum encapsulation layer. By starting with the core under tension, we offset the compressive stresses that occur during bending, enabling the conductor to handle standard bending radiuses without risk of damage to the composite core.

Our core design also reflects another crucial engineering choice: we avoid the use of glass fiber layers that would compromise performance. Glass fiber’s modulus is only one-third that of carbon fiber – adding it significantly reduces the core’s overall stiffness. This matters because core stiffness directly affects conductor performance, particularly in challenging conditions. Long spans and ice loading create substantial mechanical stress. A lower-modulus core allows greater sag, potentially violating clearance requirements. By avoiding glass fibers, our core delivers consistent performance across all operating conditions.

Critical Role of Aluminum Encapsulation

The seamless aluminum encapsulation layer serves as both protector and enabler of our conductor’s superior performance. During manufacturing, we use this thick aluminum layer to preserve the core’s critical pre-tensioned state. During installation, this same layer acts as a cushion during crimping, allowing the conductor to achieve full compaction with standard compression fittings without risking damage to the composite core. This means utilities can use their existing tools and procedures – no specialized equipment or training required.

The encapsulation layer also provides comprehensive protection against multiple threats to long-term reliability. Its seamless design eliminates the possibility of galvanic corrosion between the carbon core and outer aluminum strands by preventing the moisture and oxygen ingress necessary for this electrochemical reaction. This sealed environment also protects the composite matrix from degradation that can occur when exposed to moisture, oxygen, and other environmental factors. Even in cases where the outer strands become separated, the core remains protected from damaging UV radiation and corona-induced ozone.

This thick, seamless barrier is crucial to the conductor’s longevity. Most alternative designs rely on thin coatings or glass fiber barriers that can wear away or allow moisture penetration over time. Our thick aluminum encapsulation ensures decades of reliable protection while enabling standard installation practices – a key advantage for utilities focused on both performance and practical deployment.

Fully-Annealed Aluminum Strands

Our conducting strands use fully-annealed aluminum formed into a trapezoidal shape. This configuration allows us to pack more aluminum into the same outer diameter compared to traditional round wire designs, maximizing conductivity. The annealed aluminum provides lower electrical resistance than hard aluminum while enabling high-temperature operation.

When combined with our near-zero thermal expansion carbon core, these strands can operate at high temperatures without the excessive sag that plagues traditional conductors. This allows utilities to substantially increase line capacity while maintaining critical clearances

Performance Advantages

This integration achieves superior performance across all key metrics while maintaining the built-in safety and reliability of traditional options. The design doubles the capacity of traditional ACSR conductors while reducing line losses by 50%, enabling more efficient power delivery. Minimal thermal sag maintains critical clearances even at high temperatures, allowing utilities to increase capacity without modifying existing structures during reconductoring. For new construction, these characteristics enable longer spans with fewer structures, reducing project costs and environmental impact.

Yet these performance gains don’t come at the expense of safety or reliability. The conductor works with standard installation methods and tools, requiring no specialized training or handling procedures. Its robust design inherently protects against common failure modes – the protected core eliminates environmental degradation, the pre-tensioned design prevents installation damage, and the encapsulated construction ensures compatibility with industry-standard hardware. This means utilities can confidently deploy advanced conductor technology without compromising their rigorous safety and reliability standards.