Electric utilities face growing pressure to increase transmission line capacity. Traditionally, this has been accomplished by operating conductors at higher temperatures, with ACSS conductors designed to operate at up to 250°C. While this approach does increase capacity, it comes with significant trade-offs in efficiency and operating costs.

A Different Approach to Capacity

Modern advanced conductor technology demonstrates that substantial capacity gains can be achieved without relying on extreme temperature operation. TS Conductor’s AECC technology, for example, delivers 40-50% more capacity at normal operation temperatures:

- A stronger, lighter composite core enables the use of more aluminum

- Fully annealed aluminum provides lower resistance

These capacity increases are achieved during normal operations, typically at standard operating temperatures. While the conductor can achieve even greater capacity gains by operating at higher temperatures (180-200°C) during emergency conditions, this capability provides operational flexibility rather than being a requirement for increased capacity.

Understanding Efficiency

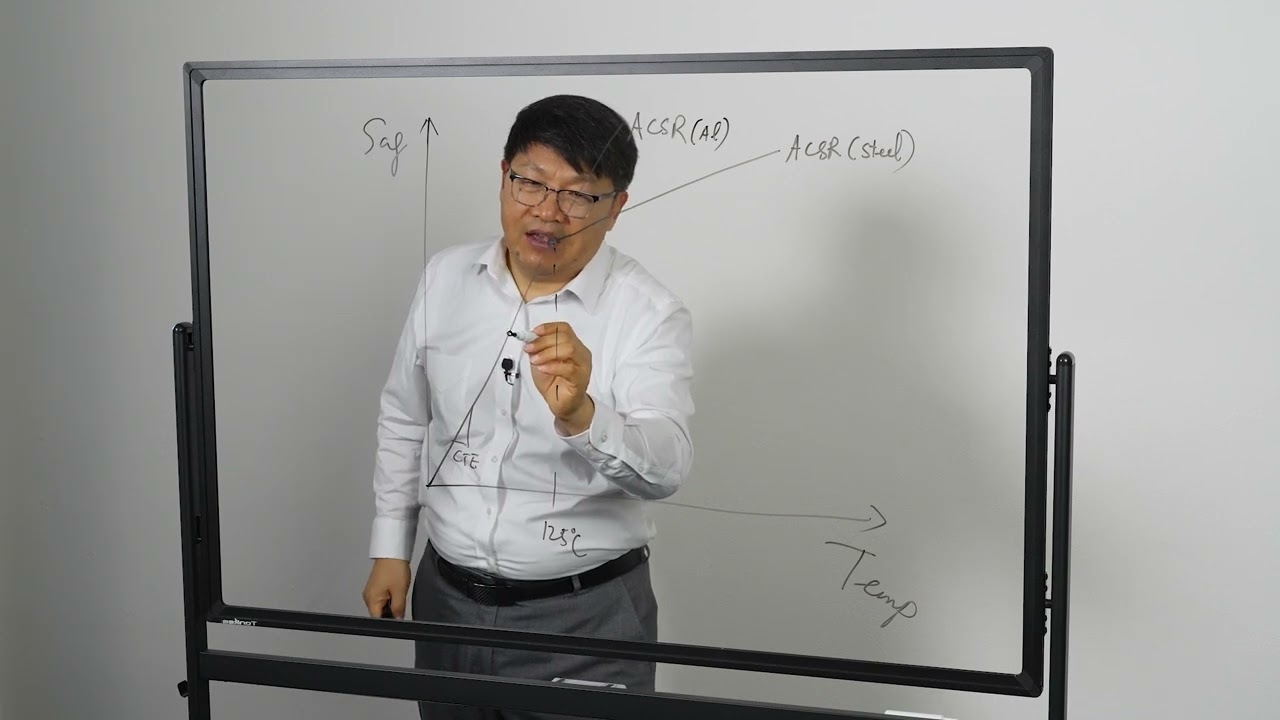

Conductor efficiency is primarily determined by electrical resistance – lower resistance means lower losses and higher efficiency. Several factors affect conductor resistance:

- Amount of aluminum in the conductor

- Conductivity of the aluminum alloy

- Operating temperature

Modern advanced conductors can achieve significantly better efficiency than traditional ACSR or ACSS conductors by optimizing these factors. At any given current level, they typically operate with lower losses due to their lower resistance and improved thermal performance.

Emergency Operations vs Normal Operations

Transmission lines must accommodate N-1 contingency scenarios, where one circuit is out of commission and remaining lines must carry additional load. During these brief emergency periods (typically 8-10 hours per year), the ability to operate at higher temperatures provides crucial operational flexibility. However, the real benefits of advanced conductor technology are realized during normal operations, where improved efficiency translates to significant cost savings and reduced environmental impact.

The Industry Context

The energy sector has made remarkable efficiency improvements over recent decades. Generation has become significantly more efficient through improved technologies and renewable resources. On the consumption side, modern appliances and industrial processes use far less energy than their predecessors. However, transmission efficiency has remained relatively stagnant, with the U.S. Department of Energy estimating that 8.3% of power is still lost in transmission and distribution.

The Path Forward

This gap in transmission efficiency represents a significant opportunity. By selecting conductors that optimize both capacity and efficiency, utilities can:

- Meet growing capacity demands

- Reduce power losses

- Lower operating costs

- Improve grid reliability

- Support sustainability goals

Current regulatory frameworks provide limited incentives for transmission efficiency improvements. However, the potential benefits—both economic and environmental—suggest that transmission efficiency deserves greater attention in grid modernization efforts.

Conclusion

When evaluating conductor options, it’s important to look beyond maximum temperature ratings and consider how capacity and efficiency goals can be achieved during normal operations. Modern advanced conductor technology offers a way to increase capacity without sacrificing efficiency, providing a more sustainable path forward for grid modernization.