For over a century, ACSR (Aluminum Conductor Steel Reinforced) has remained the standard overhead conductor technology. While several innovations have emerged to address ACSR’s limitations, none achieved widespread adoption until now. Each new generation of technology solved specific problems but introduced new challenges that prevented mainstream use. Understanding this evolution reveals why TS Conductor’s AECC technology represents the first viable alternative to ACSR in over 100 years.

ACSR: Still the Industry Standard (1908)

ACSR technology, invented in 1908, combines a galvanized steel core with hard-drawn aluminum outer strands. This design emerged from the materials limitations of its era. The steel was not strong enough, requiring strength contribution from hard aluminum strands to obtain adequate conductor strength.

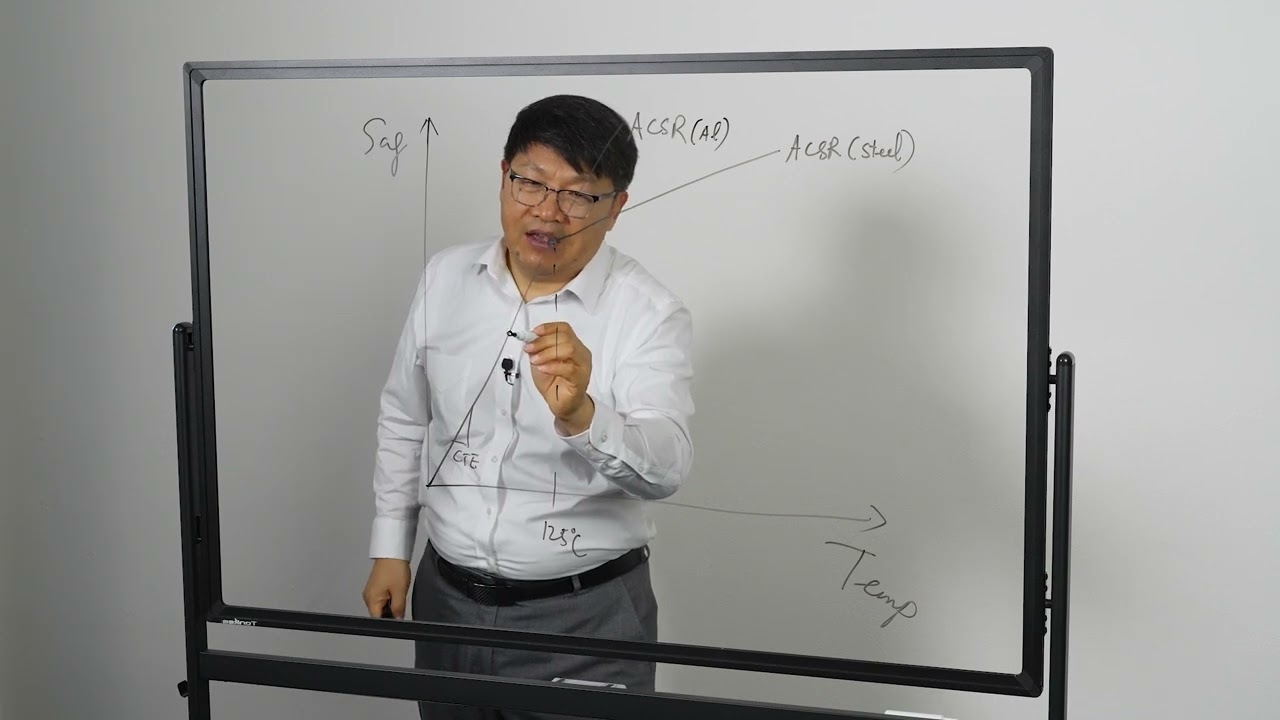

This created an inherent temperature limitation: at temperatures above 93°C (the annealing temperature), the hard-drawn aluminum permanently converts to its softer, annealed state. This metallurgical change causes permanent loss of tensile strength, leading to increased conductor sag and reduced line clearances. This temperature ceiling effectively limited current-carrying capacity, prompting the search for high-temperature alternatives.

ACSS: Solving the Temperature Problem (1970s)

ACSS technology emerged in the 1970s, leveraging advances in the steel industry that enabled the use of higher-strength steel cores. These cores, available with various protective coatings to prevent corrosion, allowed the conductor design to fully support mechanical loads using annealed aluminum strands instead of hard-drawn aluminum. This eliminated ACSR’s 93°C temperature limitation and increased capacity.

However, this solution to the temperature problem created a new challenge: excessive thermal sag. The steel core’s high coefficient of thermal expansion meant that as temperatures increased, the conductor experienced substantial sagging. To maintain required clearances, utilities needed taller structures and stronger supports. Increased structure costs limited ACSS adoption primarily to special applications where increased capacity justified the additional investment.

This limitation sparked the search for conductor technologies that could deliver both high-temperature operation and low thermal sag.

First-Generation Advanced Conductors (1990s)

The 1990s saw the emergence of composite core conductors designed to address thermal sag through the use of advanced materials. These conductors replaced steel cores with engineered composites made from ceramic or carbon fibers. The composite cores provided both high strength and low thermal expansion, enabling high-temperature operation without excessive sag.

However, these first-generation advanced conductors never achieved widespread adoption. They gained a reputation for being delicate and difficult to work with, requiring specialized installation procedures and equipment. Utilities were concerned about the risk of conductor damage during installation and long-term reliability issues. When combined with significantly higher costs compared to traditional conductors, these factors limited their use primarily to niche applications where their unique properties justified the additional expense and complexity.

The industry clearly needed a solution that could deliver advanced conductor performance while maintaining the safety and reliability of traditional conductors.

AECC: The Next Generation (2016)

AECC (Aluminum Encapsulated Carbon Core) technology represents a natural evolution that combines advanced conductor performance with traditional conductor safety and reliability. The design uses a pre-tensioned carbon fiber core protected by an aluminum encapsulation layer, paired with annealed aluminum outer strands. This configuration delivers 2-3 times the capacity of ACSR using the same structures, with half the line losses, while maintaining low thermal sag at high operating temperatures. The ability to achieve this increased capacity without structure modifications or replacements provides utilities with a cost-effective path to grid modernization.

The pre-tensioned core provides inherent resistance to compression failures during bending, while the aluminum encapsulation serves multiple functions: protecting the core from environmental exposure, providing mechanical cushioning during installation, and preventing moisture or oxygen from reaching the carbon fiber. This allows the use of standard compression fittings, dead ends, and splices – eliminating the need for specialized hardware or installation procedures.

AECC maintains complete compatibility with traditional installation methods. Line crews can use their standard tools and familiar techniques, requiring no specialized training or equipment. The robust design tolerates normal handling practices while providing protection against moisture, UV degradation, oxidation, and extreme weather events throughout the conductor’s service life.

Conclusion

AECC technology represents the first viable alternative to ACSR in over a century because it delivers superior performance through modern materials science while maintaining compatibility with standard installation practices and ensuring long-term reliability through core protection. This combination of advantages, without corresponding disadvantages, positions AECC to become the new standard for grid modernization.