The increasing frequency and intensity of extreme weather events pose significant challenges for power transmission infrastructure. A transmission line’s ability to withstand high winds and wildfires depends heavily on the inherent properties of its conductors. Understanding how conductor design affects performance under these conditions is crucial for grid reliability and resilience.

Performance in High Winds

Wind loading on transmission lines creates multiple engineering challenges. Beyond the immediate structural loads imposed on towers and poles, wind causes conductors to blow out laterally, potentially violating right-of-way limits. TS Conductor’s patented design offers distinct advantages in high-wind conditions.

The key lies in our trapezoidal wire design and compact profile. Traditional round-wire conductors present a larger wind-capture area, increasing the forces transmitted to supporting structures. Our trapezoidal wire configuration creates a smoother surface profile while reducing the overall conductor diameter. This combination delivers two important benefits: lower tension loads under wind conditions and reduced wind drag.

The effectiveness of this design approach has gained international recognition. In Belgium, for example, regulatory standards acknowledge that smooth-surfaced conductors like TS can achieve up to 40% reduction in wind-induced tension loads. Wind tunnel testing by multiple manufacturers has confirmed significant reductions in wind drag coefficients for smooth-surfaced conductors compared to conventional designs.

Wildfire Resilience

Wildfires present a different set of challenges for transmission lines. When fires burn beneath transmission lines, the intense heat can cause conductors to sag dramatically, potentially leading to catastrophic failure. TS Conductor’s design provides superior performance in these conditions through two distinct mechanisms.

First, our Aluminum Encapsulated Carbon Core (AECC) technology exhibits minimal thermal sag behavior. When exposed to the intense heat of a wildfire, TS Conductor maintains its position with minimal additional sag. This characteristic helps maintain safe clearances even under extreme heat conditions.

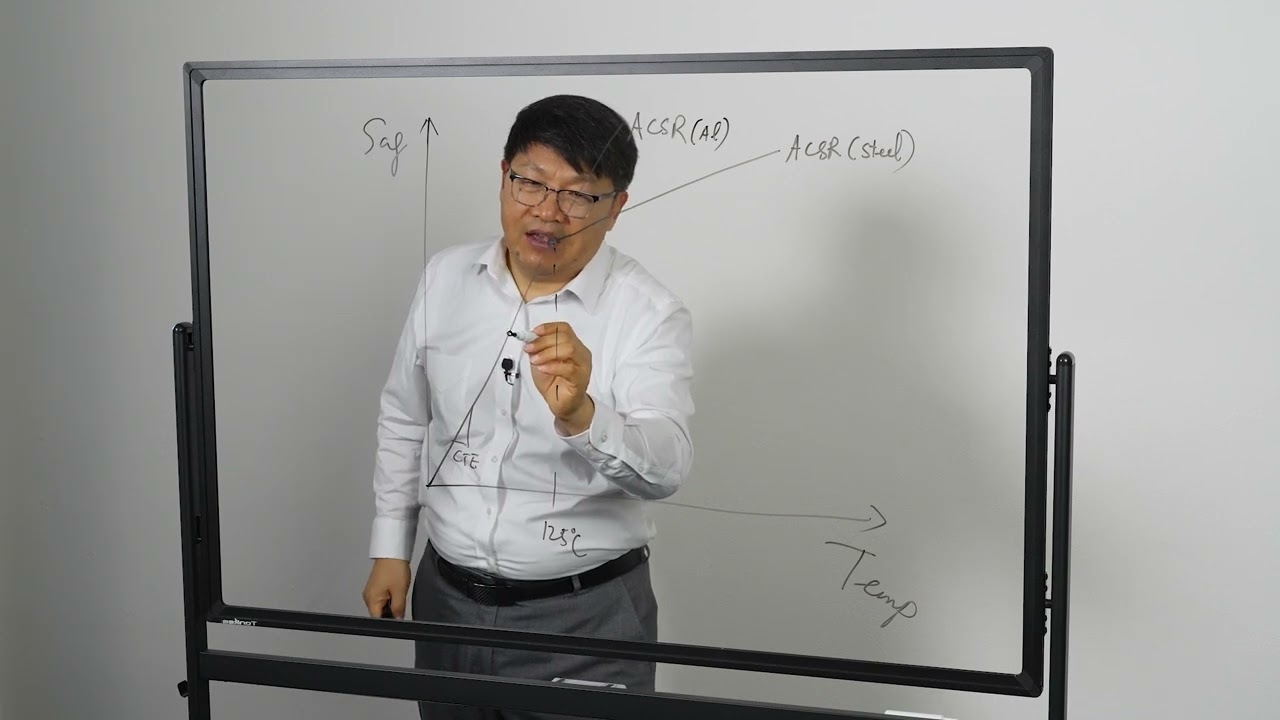

Second, our use of fully annealed aluminum means the conductor’s mechanical properties remain stable even when exposed to high temperatures. Unlike traditional ACSR conductors that use hard-drawn aluminum, there’s no risk of permanent deformation or property changes due to heat exposure.

This stands in marked contrast to conventional conductors. When ACSR conductors are exposed to wildfire conditions, they often experience significant sag, bringing them dangerously close to the flames. Even if the conductor survives the immediate fire exposure, the heat typically converts the hard-drawn aluminum to annealed aluminum, resulting in permanent sag that violates clearance requirements. In many cases, this means the conductor must be replaced entirely.

The combination of low thermal sag and heat-stable aluminum means TS Conductor installations are more likely to survive wildfire events with their performance characteristics intact. This translates to improved grid resilience and reduced maintenance and replacement costs for utilities.

By addressing both wind and fire challenges through fundamental design characteristics rather than add-on solutions, TS Conductor provides utilities with inherently resilient infrastructure. This engineering-driven approach delivers measurable performance advantages while maintaining our focus on practical, cost-effective solutions for grid modernization.