Corona discharge and electromagnetic fields (EMF) are key considerations when transmission lines pass near residential areas. Both effects can be managed through proper conductor design and configuration.

Understanding Corona

Corona occurs when a conductor’s electric field ionizes surrounding air, becoming significant above 230kV. While corona produces both power losses and audible noise, the noise impact typically draws more community concern. Corona effects increase with voltage and decrease with conductor diameter, varying significantly with weather conditions.

The TS Solution

TS Conductor offers two approaches to corona management:

- Trapezoidal wire design – optimized for maximum capacity while maintaining acceptable corona characteristics

- Round-strand configuration – specifically designed to minimize corona effects through larger conductor diameters

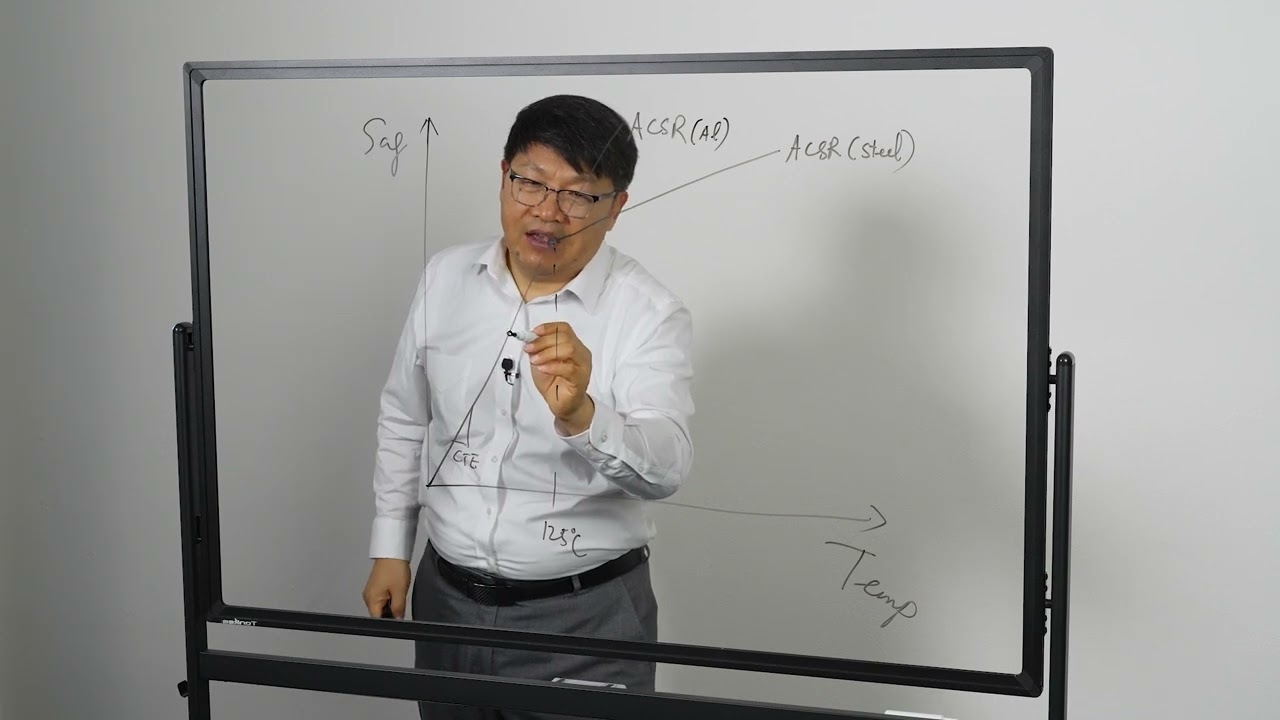

Our key advantage lies in height maintenance. TS Conductor’s minimal thermal sag naturally maintains greater clearance between conductors and ground level compared to traditional conductors. This increased height reduces both EMF exposure and corona effects at ground level, particularly at right-of-way edges where public exposure is a concern.

Traditional conductors experience significant sag during high-load conditions – exactly when corona and EMF effects peak. TS Conductor’s stable sag characteristics help maintain consistent clearance margins across all operating conditions.

Practical Benefits

For utilities, these design characteristics provide:

- Flexible corona management through conductor configuration options

- Reduced community impact through consistent clearance maintenance

- More reliable performance across varying conditions

- Greater design margin for extreme weather

By maintaining greater average clearance heights while offering corona management options, TS Conductor helps utilities address community concerns while ensuring reliable service. This engineering-driven approach delivers measurable advantages without compromising performance.