Understanding conductor ampacity requires grasping a fundamental concept: thermal equilibrium. Every overhead conductor operates within a delicate balance of heat gain and heat loss. This balance ultimately determines how much current the conductor can carry while maintaining safe operation.

Heat Balance Fundamentals

Two primary sources add heat to a conductor in operation. First is resistive heating, commonly known as I²R losses, where current flowing through the conductor generates heat. Second is solar radiation absorbed by the conductor’s surface. This heat must be dissipated to maintain safe operating temperatures.

Heat dissipation occurs through two mechanisms. Convective cooling removes heat through wind action, while radiative cooling allows the conductor to emit heat into the surrounding environment. For stable operation, heat gain must equal heat loss.

Critical Performance Parameters

Several factors influence a conductor’s thermal performance:

Wind conditions significantly impact cooling. Industry standards typically assume a conservative wind speed of two feet per second, though actual conditions vary. Wind direction also matters, with perpendicular winds providing optimal cooling.

Solar absorption depends on both environmental and design factors. Geographic location affects solar intensity, with elevation playing a particularly important role. A conductor at higher elevation experiences greater solar heating due to reduced atmospheric filtering.

Surface characteristics of the conductor determine both solar absorption and heat radiation efficiency. The industry typically uses absorption and emissivity values of 0.5, though these can be optimized through surface treatment.

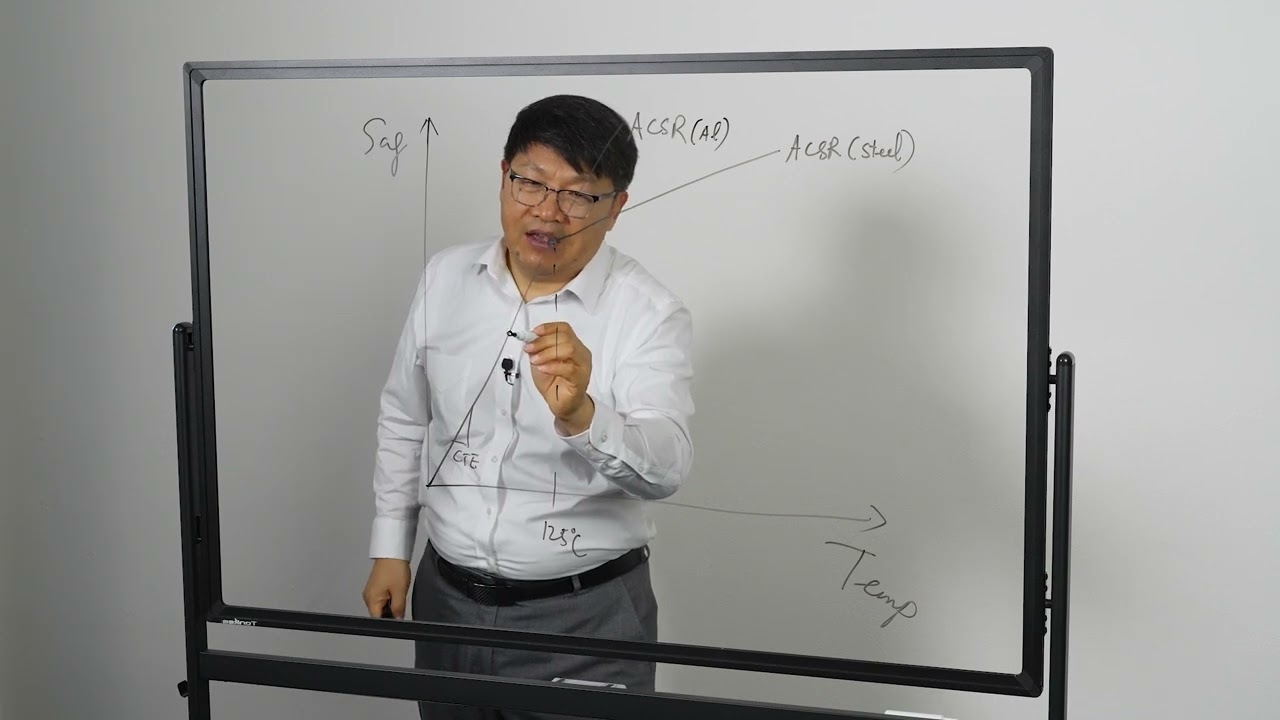

Temperature limits constrain current capacity in two ways: the conductor’s maximum safe operating temperature and the maximum allowable sag. As temperature increases, conductor sag increases, potentially violating minimum ground clearance requirements.

The TS Conductor Advantage

TS Conductor achieves superior ampacity through several design innovations. Our trapezoidal wire design and aluminum encapsulation maximize the amount of conductive material in a given conductor diameter. The high-strength carbon fiber core, smaller than traditional cores, allows more space for aluminum while maintaining mechanical strength.

The aluminum encapsulation layer serves double duty – it provides mechanical protection while also contributing to current carrying capacity. With 100% compaction and highly conductive aluminum, every bit of conductor cross-section is utilized effectively.

Dynamic Line Rating Considerations

Modern grid operation increasingly employs dynamic line rating (DLR) to optimize transmission capacity. DLR systems monitor conductor temperature and sag in real time, allowing operators to adjust current limits based on actual conditions rather than conservative assumptions.

While DLR can enable higher current capacity during favorable conditions (high wind, low ambient temperature), it may also require reducing capacity during adverse conditions. This real-time approach improves grid reliability by matching transmission capacity to actual system capabilities.