The electrical industry faces mounting pressure to increase grid capacity while minimizing costs and project timelines. Recent regulatory developments, including FERC Order 1920 and California’s SB 1006, have focused attention on reconductoring as a commonsense solution for grid modernization.

Traditional Reconductoring Challenges

Conventional reconductoring projects often trigger a cascade of costly structural modifications. When installing higher capacity conductors, excessive sag typically requires increased tower heights to maintain ground clearances. The larger conductors also create higher tension loads, necessitating crossarm reinforcement. These increased mechanical loads may even demand foundation improvements, as the original structure design may not accommodate the additional forces.

Each structural modification extends project timelines and increases costs. Perhaps most significantly, these modifications require extended outages during construction, creating reliability concerns and scheduling complications for utilities.

AECC Technology Solution

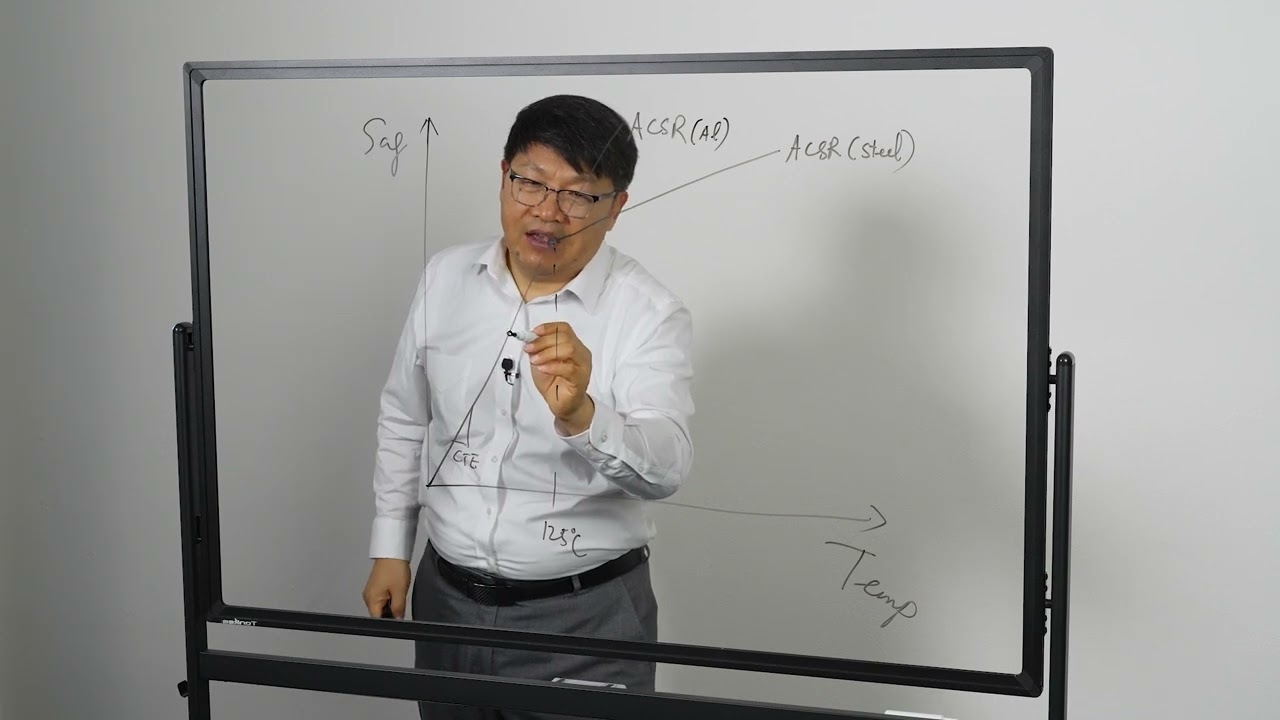

TS Conductor’s AECC technology addresses these challenges through fundamental design innovations. The carbon fiber core exhibits minimal thermal expansion while providing exceptional strength at a fraction of steel’s weight. This allows more aluminum conductor material to be added without exceeding the original structure’s weight limits. The use of fully annealed aluminum strands maximizes conductivity, while the pre-tensioned encapsulated core design enables standard installation practices.

This combination of characteristics enables sophisticated sag and tension management. The low thermal expansion of the carbon core maintains acceptable sag even at high operating temperatures. Additionally, because the conductor offers greater strength with less weight, initial installation tensions can be reduced. This ensures that under maximum ice and wind loading conditions, the forces transmitted to the structures remain within their original design limits.

Implementation Benefits

These technical advantages translate directly into project benefits. Field experience demonstrates that AECC technology can double or triple transmission capacity while working within existing structure limitations. Since no structural modifications are required, projects can be completed faster and at lower cost than traditional reconductoring approaches.

Montana-Dakota Utilities’ Napoleon-Heskett project illustrates these benefits. The 15-mile 230kV reconductoring project increased ampacity by 77% while reducing estimated costs by 40% compared to traditional solutions. By avoiding structural modifications, the project was completed a full year ahead of schedule.

This technical solution aligns with the industry’s need for faster, more cost-effective grid upgrades. By addressing the core engineering challenges of traditional reconductoring, AECC technology provides a practical path to increased grid capacity without the cascade of structural modifications that historically made such projects costly and time-consuming.