In transmission line design, conductor sag must be carefully evaluated to ensure adequate ground clearance under all conditions. There are three fundamental types of sag that must be considered: thermal sag, creep sag, and load-induced sag.

Thermal Sag

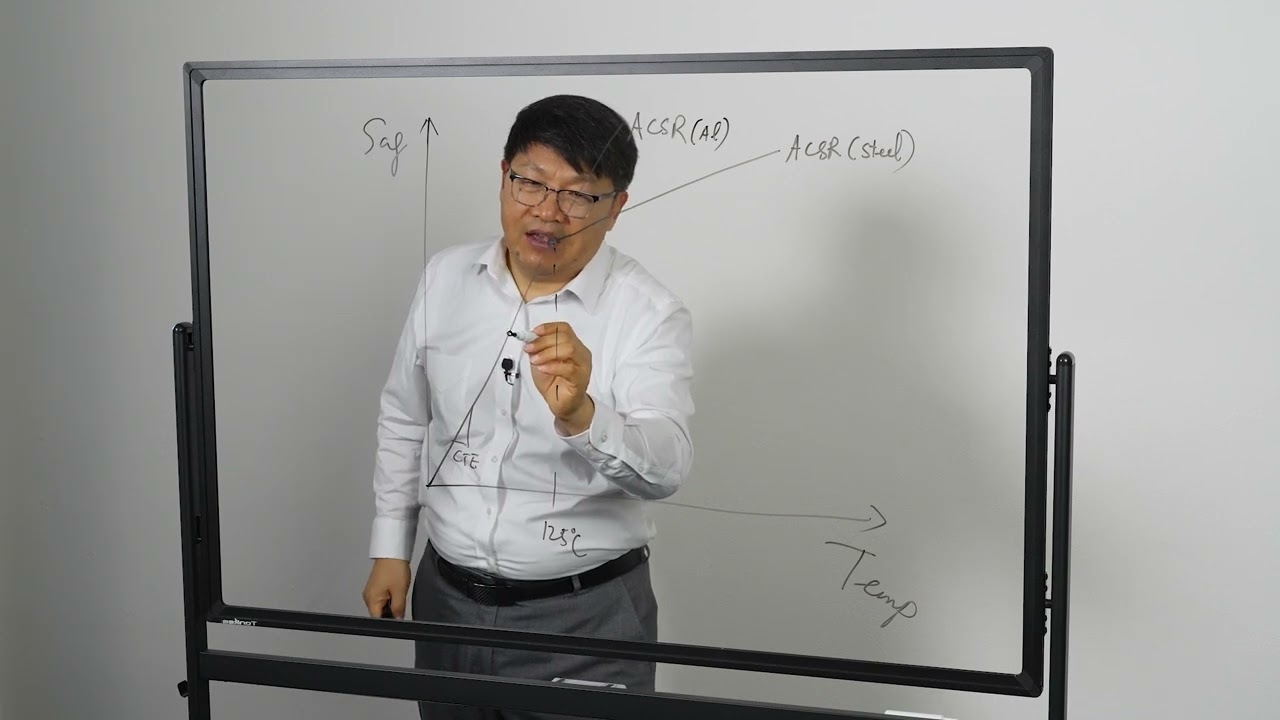

Thermal sag occurs as conductors heat up and expand during operation. The amount of thermal sag depends primarily on the core material’s coefficient of thermal expansion. Traditional steel-core conductors experience significant thermal sag due to steel’s relatively high thermal expansion coefficient. In contrast, composite core conductors use materials with much lower thermal expansion coefficients, resulting in significantly reduced thermal sag.

Creep Sag

Creep sag develops over time as conductor materials, particularly aluminum strands, gradually elongate under sustained mechanical loading. This is especially significant in conductors without dedicated strength members, such as AAC (All Aluminum Conductor) or AAAC (All Aluminum Alloy Conductor).

Traditional industry practice has been to project ten-year creep behavior based on relatively short-term laboratory tests (around 1,000 hours). However, this approach often underestimates long-term creep, as aluminum strands can continue to elongate well beyond the ten-year mark in conductors without dedicated strength members.

Load-Induced Sag

Load-induced sag occurs when external forces, primarily ice and snow accumulation, add weight to the conductor. The total load includes:

- The conductor’s own weight

- Accumulated ice and snow weight

- Span length effects (longer spans mean more total weight)

A conductor’s response to these loads depends largely on its core’s elastic modulus. First-generation composite core conductors, which incorporated significant amounts of fiberglass, exhibited lower modulus values that could result in excessive load-induced sag. This contributed to a perception that all advanced conductors have sag problems under heavy loading.

Next generation advanced conductor AECC takes a different approach. By eliminating fiberglass, it achieves a respectable modulus that effectively manages load-induced sag. This enables the conductor to handle heavy ice loads and support longer spans, including major river crossings like those over the Mississippi River.

Comparing Sag Performance

TS Conductor’s AECC technology effectively addresses all three types of sag through its unique design:

Thermal sag is virtually eliminated above the knee point temperature. This is because once the fully annealed aluminum transfers its load to the carbon fiber core, any further temperature increase causes minimal thermal expansion due to the core’s extremely low coefficient of thermal expansion.

Creep sag is minimal because the carbon fiber composite core maintains its strength and dimensional stability over time. Unlike aluminum conductors that continue to elongate, or traditional designs where aluminum strands may creep, AECC’s core provides long-term mechanical stability.

Load-induced sag is effectively managed through the core’s respectable modulus. AECC’s carbon fiber core provides sufficient mechanical strength and modulus to handle ice and snow loading while maintaining appropriate sag levels for reliable operation. Aluminum alloy options are also available, should it be required for special project situations.