TS Conductor’s AECC is the only advanced conductor that is fully compatible with traditional ACSR/ACCC installation and maintenance practices. While first-generation advanced conductors gained a reputation for being delicate, difficult to work with, and easy to break – requiring specialized training and equipment, TS Conductor has solved all of those problems with its patented design. Instead of demanding perfect installation technique, AECC is designed to be inherently robust and forgiving during installation and maintenance.

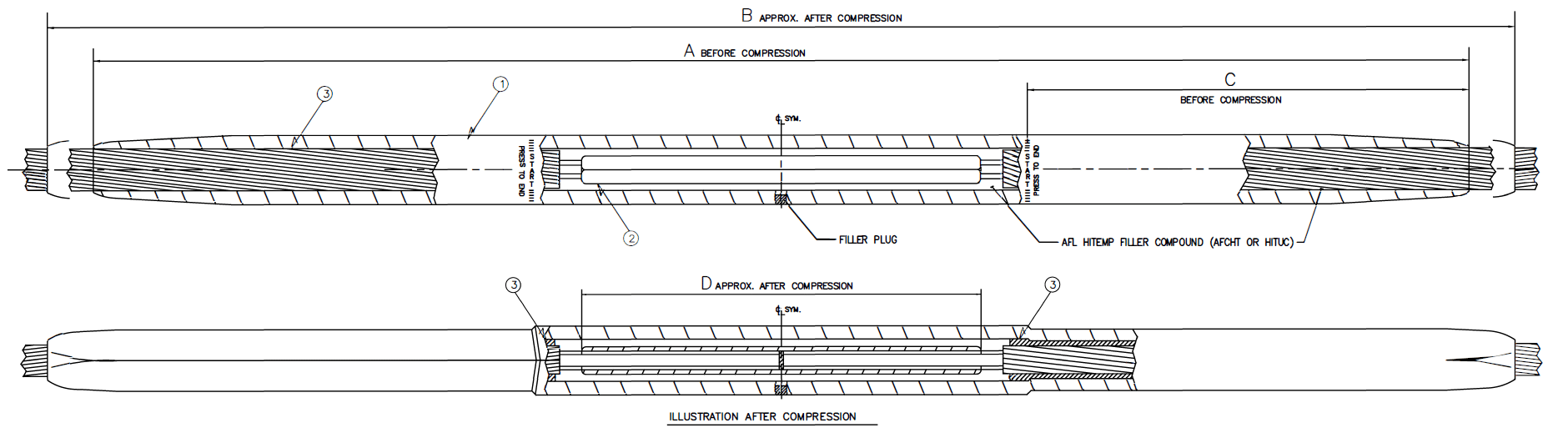

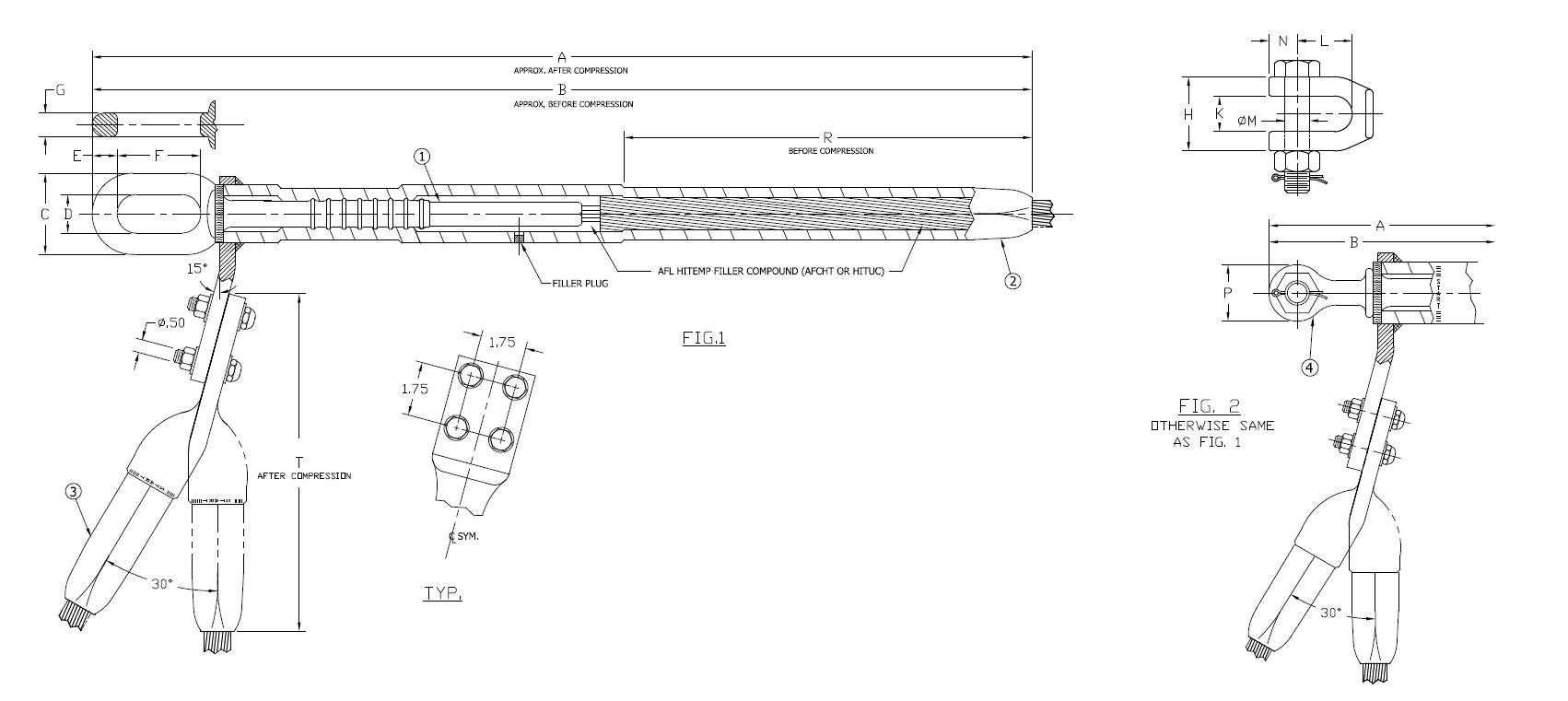

Standard Compression Fittings

The aluminum encapsulation layer is a key innovation that enables standard installation practices. During compression fitting installation, this layer acts as a protective cushion for the carbon composite core. When properly compressed, the fittings achieve 100% compaction around the core, creating an airtight seal that prevents moisture and oxygen ingress.

This design allows line crews to use their standard compression tools and dies – the same ones used for ACSR installation. There’s no need for specialized equipment or training. Whether installing deadends or splices, crews can follow their familiar procedures while achieving reliable connections.

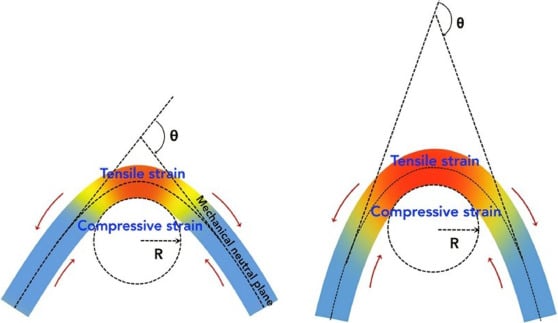

Standard Bending Radius Requirements

AECC’s robustness stems from its pre-tensioned carbon core design. During manufacturing, the core is placed under tension before being encapsulated in aluminum, creating a stable composite structure. This pre-tensioning, combined with the encapsulation’s structural support, enables the conductor to resist compression stress during bending without experiencing core buckling or breakage.

The recommended minimum bending radius for AECC is 25 times the conductor’s outer diameter, matching IEEE 524 standards for traditional conductors. Importantly, this limitation comes from preventing birdcaging of the annealed aluminum strands rather than any core constraints. This means utilities can use their existing stringing blocks and equipment without modification.

Image Source: Science Direct

Standard Storage Conditions

The sealed nature of AECC eliminates the special storage requirements that plague other advanced conductors. The aluminum encapsulation completely protects the carbon core from moisture ingress, which can compromise bare composite cores by softening their polymer matrix and reducing compressive strength – a process called plasticization.

This protection begins during manufacturing, where 100% X-ray inspection ensures encapsulation integrity, and continues throughout the conductor’s life. AECC can be stored in standard conditions for years without degradation, simplifying inventory management. The conductor maintains its full mechanical and electrical properties even after extended storage or exposure to challenging environmental conditions, ensuring reliable performance when needed.

Through these design innovations, AECC technology achieves advanced conductor performance while maintaining the practical installation and maintenance characteristics that utilities expect from traditional conductors. This combination of performance and practicality enables faster adoption and more reliable long-term operation.