In typical U.S. transmission line projects, conductor costs represent approximately 5% or less of total project costs, while structure-related expenses can reach 30%. This cost distribution is crucial for understanding where potential savings can be realized. The relatively small percentage allocated to conductors means that even premium conductor solutions can be economically advantageous if they enable savings in structural costs.

Economic Benefits for New Construction

While advanced conductors are often viewed primarily as a reconductoring solution, they also offer compelling economics for new construction projects. TS’s AECC technology enables longer spans between structures due to their superior strength to weight ration and sag characteristics. This capability translates directly into fewer required structures and often allows for shorter structure heights. The result is often 10-20% lower total project costs through reduced material, labor, and land acquisition expenses.

Florida Power & Light’s 5-mile 230kV Eldora-Finca-Heritage rebuild demonstrates these benefits. The project increased ampacity from 1,495A to 3,000A – a 114% improvement – by reducing structure heights by 20 feet. These optimizations resulted in $2.5 million in total project savings compared to traditional conductor solutions.

Reconductoring Economics

The economic case for reconductoring with TS is even more attractive. By replacing just the conductor – representing 5% of asset value – utilities can achieve dramatic capacity increases without modifying existing structures. This approach can reduce project costs by 30-40% compared to traditional reconductoring solutions.

Montana-Dakota Utilities achieved these results in their 15-mile 230kV Napoleon-Heskett reconductoring project. The utility increased line ampacity by 77% while reducing estimated costs by 40%. The project was completed one full year ahead of schedule and delivered $1.8 million in total savings.

Technical Advantages Enabling Economic Benefits

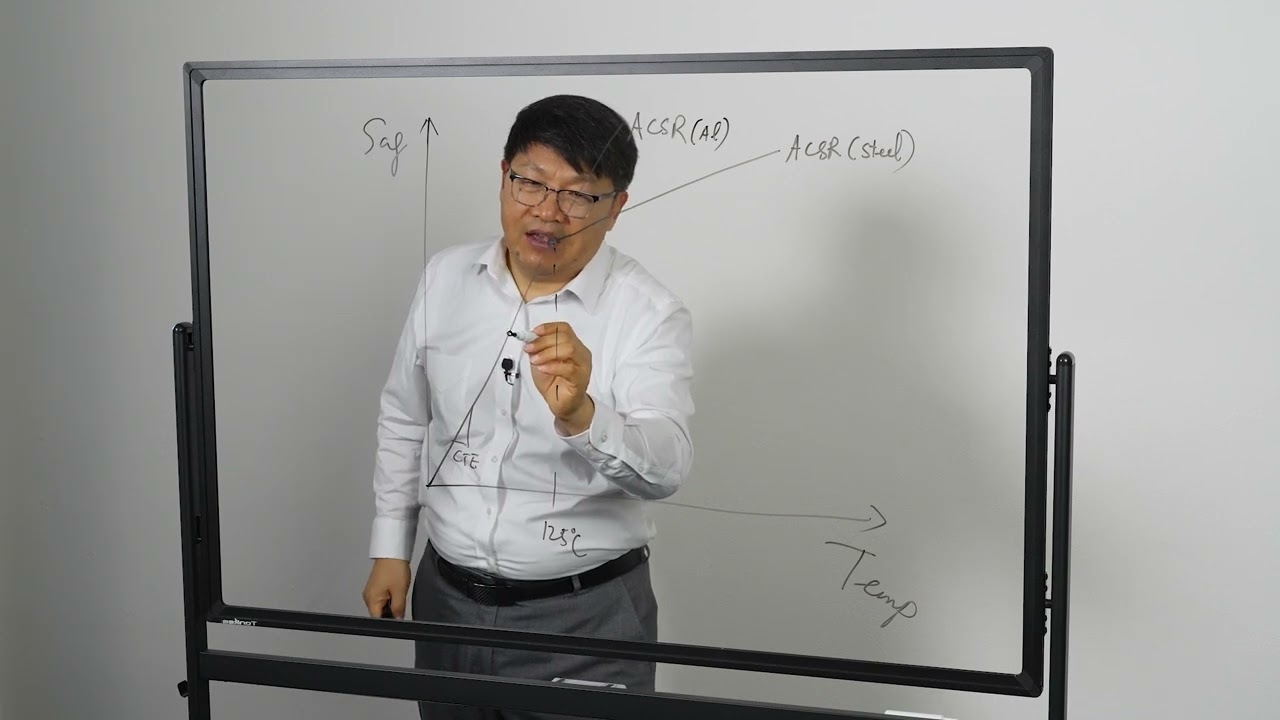

The economic benefits stem from TS Conductor’s fundamental design advantages. The carbon fiber core provides exceptional strength while weighing significantly less than traditional steel cores, allowing more aluminum to be added without increasing overall conductor weight. The use of fully annealed aluminum strands – which offer superior conductivity compared to hard-drawn aluminum – combined with the additional aluminum content significantly increases ampacity. Simultaneously, minimal thermal expansion of the carbon core results in dramatically reduced sag at high temperatures.

These technical advantages combine to create a unique value proposition: utilities can double or triple throughput while only investing in the conductor portion of the transmission asset. This represents a far more capital-efficient approach to grid modernization compared to traditional solutions requiring complete structure replacement or new corridor development.

Future Considerations

Looking ahead, the industry has an opportunity to further enhance the economic benefits of advanced conductors by developing mechanisms to monetize efficiency improvements. If line loss reductions could be factored into project economics through regulatory frameworks or market mechanisms, it would strengthen the already compelling case for grid modernization using advanced conductor technology.

For transmission engineers facing grid modernization challenges, advanced conductors have evolved beyond niche applications to become a mainstream solution for cost-effective grid expansion and upgrading. The technology delivers substantial capacity increases while minimizing capital expenditure, providing a practical path to grid modernization.