Florida Power and Light (FPL).

Project overview.

Technology.

FPL compared the TS Williamson M3 10 (2093 kcmil) conductor with the 1926 ACSS Cumberland, ultimately selecting the TS solution.

Challenges.

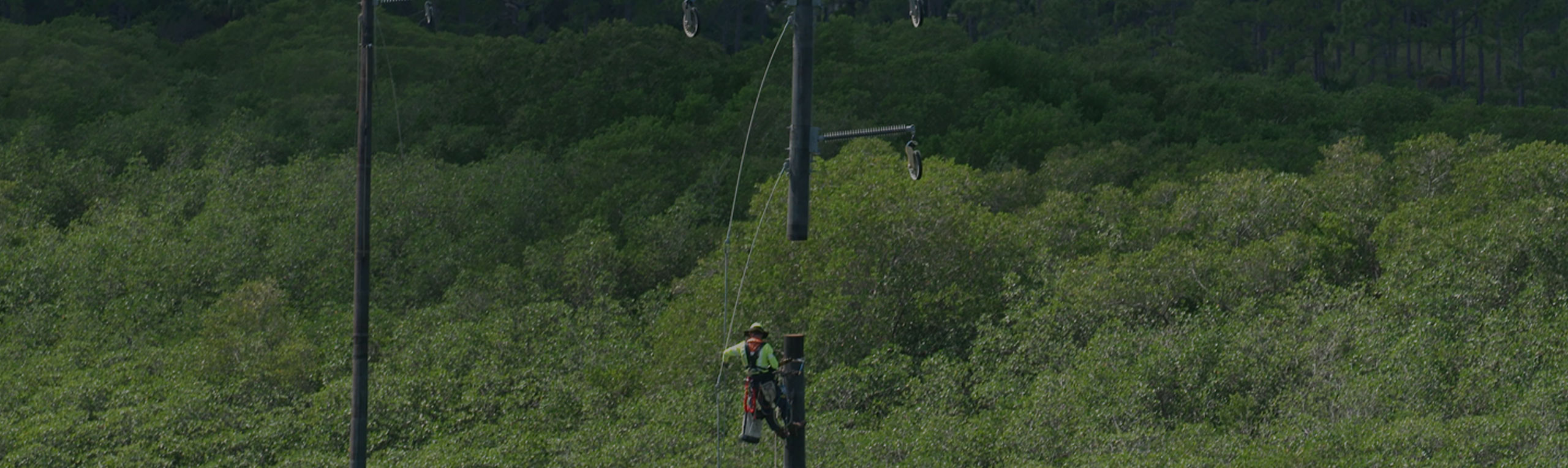

This rebuild presented unique challenges due to its location in a water management right-of-way (ROW). Specific easement requirements to ensure access to the waterway for maintenance meant that tower locations and ruling spans were fixed and pre-determined, limiting FPL's design flexibility.

Key outcomes.

TS Williamson reduced thermal sag by over 7' compared to ACSS at maximum operating temperature. This allowed FPL to use smaller, simpler 120', 32 kip single-piece structures instead of the 140', 45 kip two-piece structures required for ACSS. TS Conductor's compatibility with standard installation practices and equipment helped ensure worker safety and keep the project on schedule and within budget.

Increased capacity from 1,495 Amps to 3,198 Amps, surpassing the original 3,000 Amp requirement.

Reduced total structure and conductor costs by over $2.5 million compared to the ACSS option.

Met unique ROW constraints while providing additional capacity for future flexibility